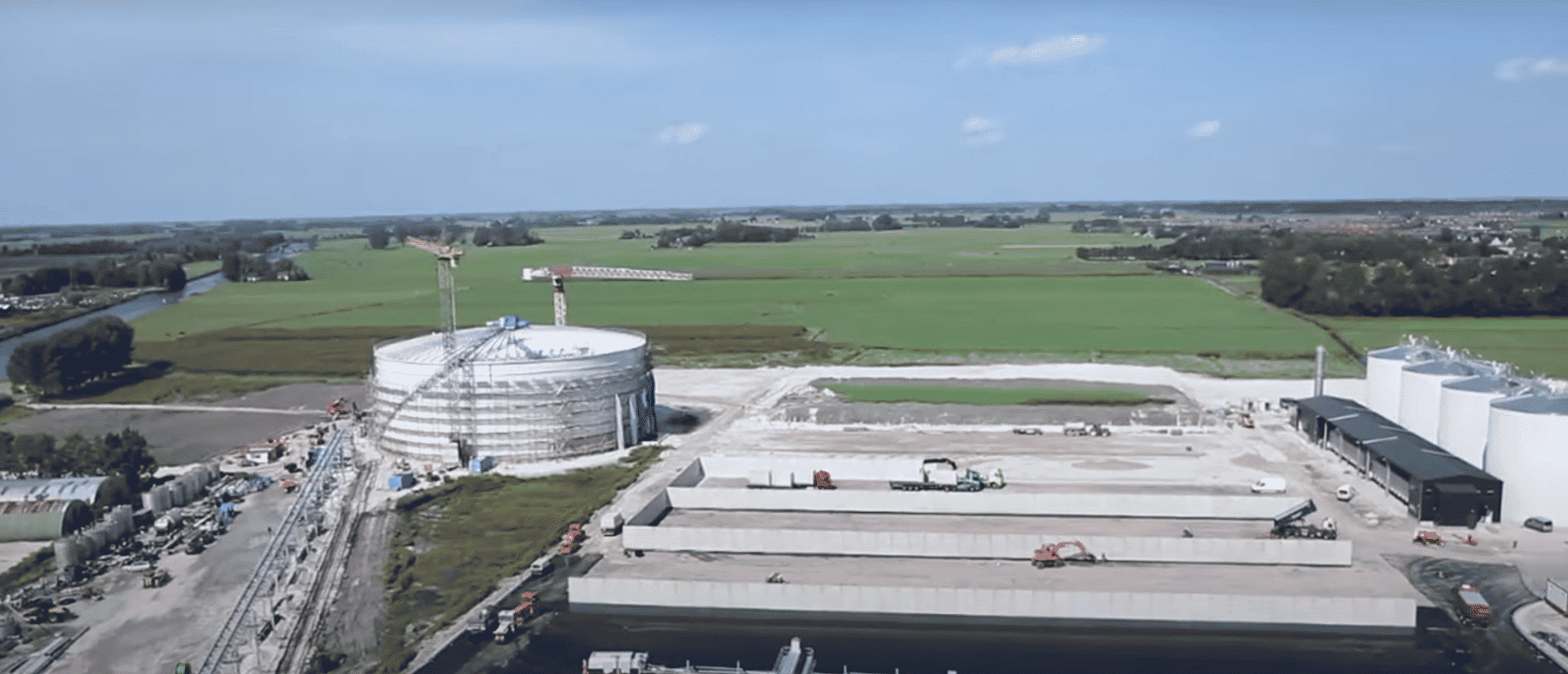

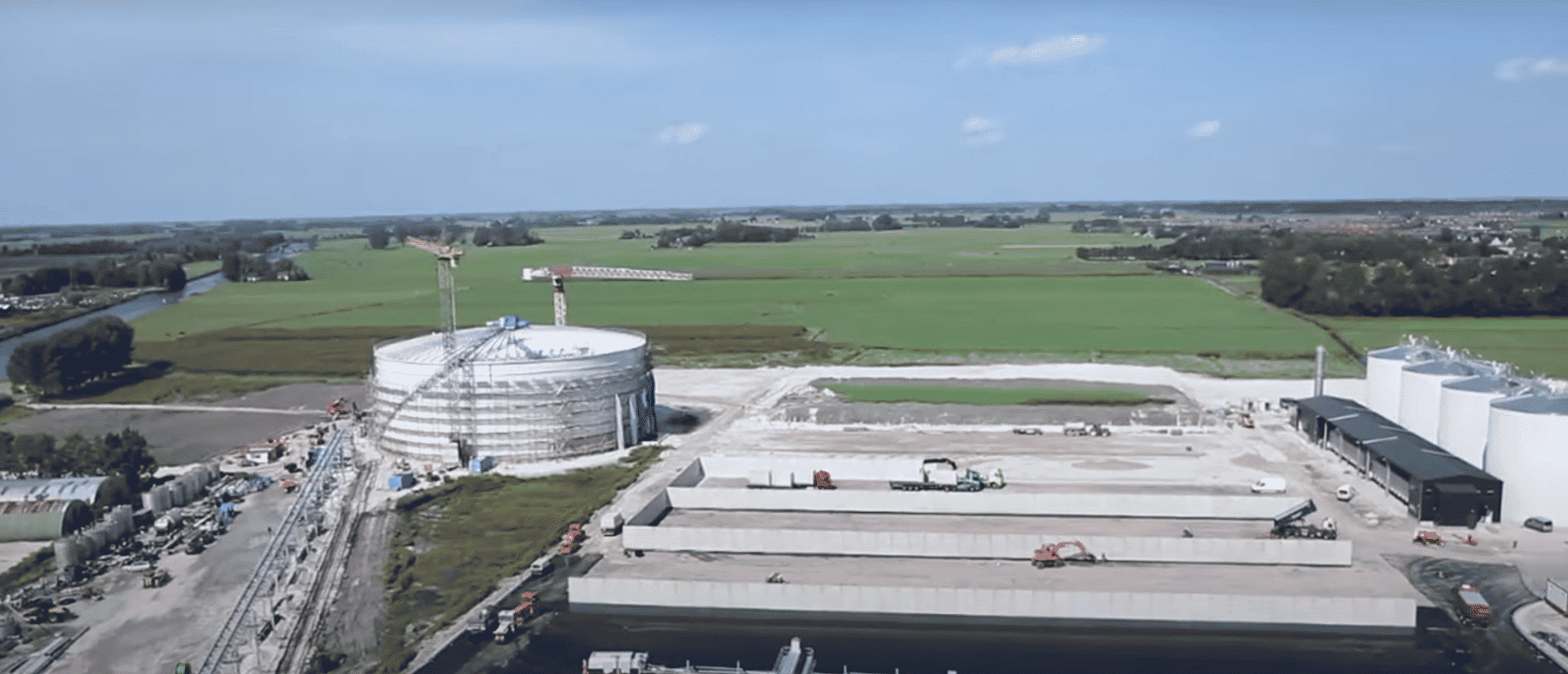

Suikerunie stores 100,000 tonnes of pressed pulp

These days, Cosum Beet Company (formerly: Suikerunie) extracts everything from sugar beet, more than just sugar. It is a source of innovative solutions for current societal challenges and a sustainable future. Suikerunie was already involved in this in 2012 when Bosch Beton installed retaining walls for eight silage clamps for the storage of pressed pulp for the sugar beet processor.

We were contracted to build eight silage clamps for the storage of 100,000 tonnes of raw material for a Suiker Unie Green Energy biodigester plant. The silos’ retaining walls are 110 metres long and over 27 metres wide with partition walls of 4 metres high. This contract comprised a total of 420 elements for which we carried out the calculations, delivery and installation.

Pressed pulp

When processing sugar beet a residual product remains: pressed pulp. Suikerunie then used this residual product as fuel in a new biodigester plant on its own grounds. The choice for high-strength concrete will considerably delay the impact of acids during storage.

Customised solution

Bosch Beton created a customised solution for the corners in the rear wall. The corners were poured together with the retaining walls, ensuring that the walls connect seamlessly.

The installation of the TW retaining walls went quickly: 170 metres of retaining wall per day. Ten trucks ran from and to the Bosch Beton plant, at that time still located in Kootwijkerbroek.

Suikerunie’s decision to work together with Bosch Beton was based on price, the contribution of ideas and the fact that the walls were better than those offered by other suppliers.

Further information

If you would like to know more about this project or our customised retaining wall solutions for storage, please feel free to contact our consultants.

Build your own silage clamp

Use the Bosch silage clamp generator to build and submit your own virtual silage clamp in three steps. You will receive a non-binding advice within three working days of submission.

Project in the picture

Similar projects

Retaining walls as foundation for sound barriers along the N206

Bosch Beton increasingly more often is being approached for supplying retaining walls for sound barriers along motorways. Thus it was also approached for the construction of the RijnlandRoute near Katwijk.

Three new silage clamps for a bull breeding farm in France

A bull breeding farm in the French region of Picardy was looking for an expansion in roughage storage to provide its growing number of bull calves with sufficient roughage throughout the year.

Retaining walls enrich Fraxern mountain village in Austria

In the Austrian state of Vorarlberg, local contractor Andreas Lins became familiar with Bosch Beton retaining walls around 2016. Since then, many houses and gardens in the region have been enriched with a solid retaining wall solution from Bosch Beton.