Cover systems

Silage clamp walls are increasingly being combined with an automatic cover system. Configuring high silage clamp walls with an automatic cover system enables each grass cutting to be ensiled layer by layer in one silo, creating so-called lasagna silage. This improves feed consistency, resulting in higher milk production and a higher balance per cow. Bosch Beton has developed special silage clamp walls that are a perfect match for automatic cover systems.

High-quality roughage forms the basis for higher milk production and a higher balance per cow. This roughage concept optimises the uptake of nutritional values, as all grass layers are ensiled horizontally on top of each other throughout the growing season. The first cuts of grass contain a lot of energy, while the later cuts tend to contain more structure and protein. Even distribution is ensured by ensilaging different cuts in layers over the entire surface of the silo. Cutting out lasagna silage vertically with sufficient feed rate ensures more consistent and complete roughage quality.

Advantages of a lasagna pit:

- Ensilage in layers is possible

- Minimum physical effort when opening your silage

- Adaptable to your feed rate

- Higher milk yields through improved feed consistency

- Savings on concentrated feed

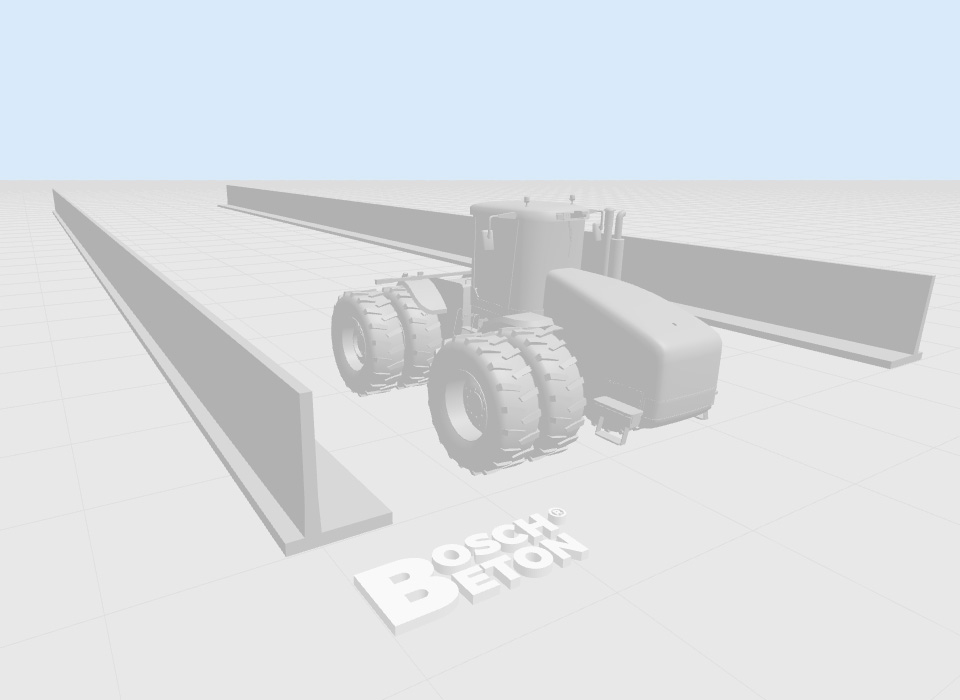

LAH retaining walls

The LAH retaining wall was developed especially for the cover system principle. The wall has an extra-long heel and a reinforced structure. This means that, when covering and removing silage, the cover system moves across the stable heel along the silage clamp walls. The walls can be placed directly on a sand bed, gravel bed or mortar. This saves both on construction time and on additional building materials and costs.

5 advantages

The new walls have several advantages:

- Extended heel for automatic cover systems

- High stability due to large bearing surface

- 15-tonne axle load up to the edge

- Concrete quality C60/75

- 15-year guarantee

Agridek cover innovation

Agridek offers several innovative cover systems to optimise the lasagna silage method results. As each dairy farmer is different, each feed concept is also different. Combining good advice and guidance towards the right cover solution ensures that the investment is profitable. Agridek works closely with Bosch Beton to advise livestock farmers on roughage storage, silage clamp dimensions and cover methods for their current or future situation. With the Agridek cover system, the silage clamp can be covered by just one person.

Build your silage clamp

Using our 3D generator, you can build your own silage clamp in three steps Decide what you are going to use the silo for, select a silage clamp wall type, and enter the dimensions of your silage clamp along with the axle weight. Make a selection for the paving of the farmyard, and any accessories and services required. You will receive a customized recommendation free of obligation within three working days of receipt of your application. If you would rather have personal advice, please contact our team.