Carbon labels on retaining walls: How and why?

Bosch Beton and many other concrete industry manufacturers are facing the challenge of making the carbon impact of our concrete retaining walls more concrete. With a focus on sustainability, we have developed an innovative approach to measuring and communicating this impact using the ‘well-known’ carbon sustainability label, with various classes. This sustainable and transparent initiative offers customers and consumers essential information about the environmental impact of products, enabling them to make informed choices

The power of EPD

A crucial part of this initiative is using an EPD (Environmental Product Declaration). An EPD is a document that provides detailed information about the environmental impact of a construction material or product throughout its life cycle. This offers customers insight into factors such as carbon emissions per unit of concrete or of specific products.

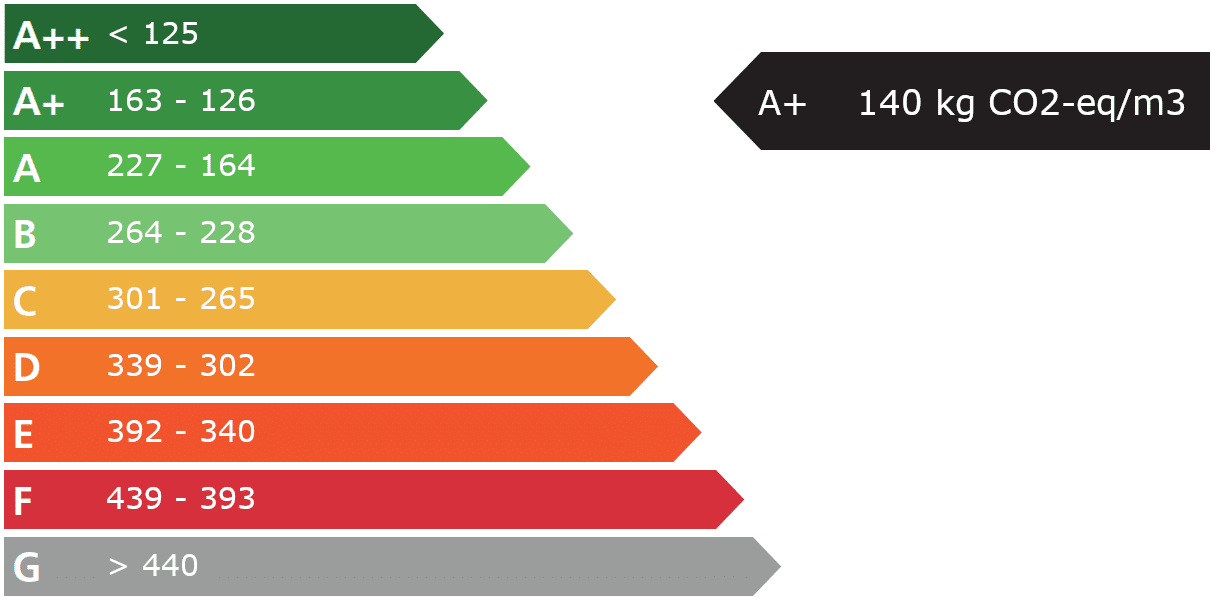

Image: Carbon label of our 1st Cement-free Generation mixture.

Purpose of carbon labelling and benchmark

In our efforts to establish carbon labelling for our concrete products, we based our benchmark on the Green Construction Board’s (GCB) Low Carbon Concrete Group (LCCG) study from the UK. They developed a seven-step plan, in which carbon-free, waste-free, biodiversity and environmental gains form the basis of the ratings. To obtain the dataset for the classifications, GCB analysed a total of 624 different concrete recipes within strength classes C8/10 to C80/95, providing a good bandwidth for concrete products of different strength classes.

Cradle to cradle instead of cradle to gate

We are also using a ‘cradle-to-cradle’* (A1-D) approach in our carbon labelling. This goes further than the LCCG study, which still used ‘cradle to gate’** (A1-A3). This is because we believe it is important that products are presented with total transparency, from the proverbial cradle to cradle rather than just until the product leaves the factory gate.

* In our case, ‘cradle to cradle’ literally means that after a retaining wall’s entire life cycle, it becomes the new raw material for a subsequent product.

** This approach assesses a product only up to the point at which it leaves the factory. The use and waste phases, for example, are not included in this approach.

The working method behind the measurements

The carbon impact measurement process adheres to strict standards and methodologies. We use the LCA methodology, certifications according to the latest ISO 14040 and ISO 14044 standards and the analysis complies with the ‘environmental performance of construction works’ assessment method version 1.1, March 2022. This involves analysing the environmental impact throughout the product’s life cycle, from raw material extraction to production, use and finally disposal. The result is an overview of a product’s environmental impact, which also includes carbon emissions.

Innovative approach to measurement

Bosch Beton has introduced an innovative approach by validating the results of its walls and content and by measuring all mixtures per cubic metre. This enables integration of these validated results in a calculation tool that can calculate the combination of all the different elements, from raw material extraction, transport, placement and a product’s end-of-life. It is a way to clarify a product’s entire carbon impact.

However, according to the standards, using this method to merge validated EPDs does not yet automatically lead to a validated EPD on the overall calculation, although this can now be requested, allowing us to offer our customers a fully validated carbon calculation per construction project!

Transparency

This transparent and detailed approach enables both Bosch Beton and its customers to make informed decisions based on documented and validated information about a product’s carbon impact.

Our commitment to ‘unveiling’ and communicating our products’ environmental impact illustrates a growing construction sector trend. It emphasises the need for transparency and sustainability in enabling consumers to make conscious choices that contribute to a greener future.

We recognise that we need a greater, more representative dataset for more precise classifications of the higher strength classes, and we remain alert for changes in future publications based on the evolving dataset.

News

Winners Bosch Beton silage clamp win campaign announced!

The drawing of our silage clamp win campaign took place recently. The notary came by to draw two winners and...

Bosch Beton collaborates with FLC for the Fehmarnbelt project

Fehmarn Link Contractors (FLC) has chosen Bosch Beton to supply concrete barriers for a tunnel which will enable a shortcut...