Bosch Beton prepares for the future

Concrete producer devours former factory

Sustainability is a high priority for Bosch Beton. This has only increased following the commissioning of the new factory and the subsequent acquisition in 2019. But sustainability is also important with a view to the future, the next generation. Because you need to think about tomorrow today. How does Bosch Beton implement sustainability in practice?

Building a solid future

If we want to continue to exist and build towards the future, we need to think about this today. The sustainability transition needs to take place now. Concrete is a reliable construction material, but the raw materials are finite. That’s why we keep on innovating, developing and improving our sustainability to continue to make and deliver a high-quality and sustainable product. Bosch Beton is the first retaining wall producer to receive the CSC Gold certificate. This certificate demonstrates that we produce our concrete products in a sustainable and responsible way. Our objective is for a 100% circular retaining wall production.

Sustainable and energy neutral

We have so many ideas and initiatives about sustainability. This is reflected in such things as the state-of-the-art factory in which Bosch Beton has been located since June 2019. For the new factory, we studied various technologies to enable sustainable and energy-neutral prefab production. The production location exudes sustainability throughout. We reuse rainwater in our production process. The over 18,000 solar panels on the roof provide power. And, as we use sustainable materials, installations and recycled products, we can proudly state that our concrete retaining walls are a sustainable product.

Recyclable green retaining wall

Last summer we added the green retaining wall to our range. The idea for the green retaining wall was born in MVO Nederland’s Concrete Network, to which Bosch Beton is affiliated. Over twenty concrete companies in this network are working hard for a more sustainable concrete sector.

As well as retaining soil, our green retaining wall provides somewhere for plants and insects to thrive. Unlike other concrete walls, the green retaining wall encourages the regrowth of rapidly declining biodiversity in the Netherlands. The choice of high-quality raw materials that can be reused after the wall has been dismantled makes it fully recyclable. The green retaining wall project is part of the Societal Programme for Natural Capital.

» Discover more about the recyclable green retaining wall

Sustainable platform walls

We are working with various partners in the Netherlands on ProRail’s ‘Standardised Platforms’ project, for which we are supplying sustainable retaining walls. The shape of the special platform walls has been optimised and we are producing these using a new sustainable concrete mixture. The elements are KIWA certified in accordance with the latest ProRail product specification. The walls meet the necessary ECI values (Environmental Cost Indicator), one of the reasons why Bosch Beton was selected. As we produce walls in two-metre lengths instead of one-metre lengths, our material use is more efficient and we make savings on transport. In 2021, ProRail will be renovating seventeen stations of the approximately seventy platforms that need replacing.

ECI value of our retaining walls

We are the first retaining wall supplier in the Netherlands to receive a verified Life Cycle Analysis (LCA) on our retaining walls. For this, we calculated our ECI value, together with the certificating bodies. The ECI is a fictive price that reflects the costs you would need to make to compensate for the negative environmental impact of producing a product. In the future, projects must be implemented in a climate-neutral and circular way so that they contribute to a sustainable living environment. Rijkswaterstaat is, for example, focusing on low ECI values to achieve the climate-neutral objective by 2030 as well as realise a circular building sector. In this way Rijkswaterstaat is stimulating the market to develop sustainable innovations.

Devouring former factory

Bosch Beton’s roots lie in Kootwijkerbroek, on Wesselseweg. We produced our concrete retaining walls here for some fifty years. Countless retaining wall freight consignments left here for destinations at home and abroad for a wide range of agricultural and civil engineering projects. Following the commissioning of the new factory in Barneveld, the production of prefab retaining walls has increased considerably. We are reusing the foundations of the former factory and processing this into granulate. The 20,000 tonnes of rubble will then form new raw material for the production of high-quality retaining walls. And this is entirely in line with Bosch Beton’s sustainability ambition.

The former factory site of some twenty hectares is also being given a new function: Zonnepark Branderwal with its 75,000 solar panels is due for completion by end 2022.

Second lease of life

Innovating, developing and enhancing our sustainability enable us keep improving our product quality. Today we can produce much thinner and more sustainable walls using less materials than fifty years ago. Bosch Beton became famous for its substantial buttress walls. We are still sometimes asked about these robust walls from yesteryear, which isn’t so strange as these walls were the strongest on the market at that time. We regularly visit customers who ask whether we can move their walls. Sometimes the walls have been standing in all weathers for over twenty years but have lost none of their integrity; evidence that Bosch Beton retaining walls will last for generations. Our permanent crane partners can move the walls so we can give old walls a second lease of life. This is also entirely in line with our ideas about sustainability.

Sound partner

We see our customers as partners with whom we build a sustainable, sound and future-proof relationship. This means that we always offer personal advice that is honest and sincere. Only in this way can we work with our customers to develop the best customised solution.

If you would you like to know more, feel free to contact one of our consultants. We’re happy to help.

Latest news

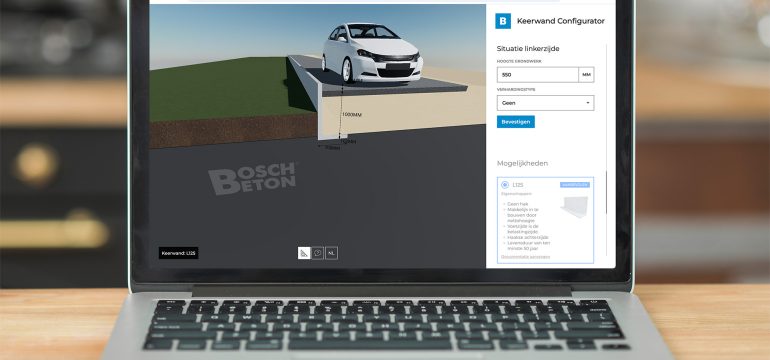

New: the Retaining Wall Configurator

Bosch Beton's Retaining Wall Configurator allows you to select a structurally sound retaining wall for your project in a few...

New: Green Series

“Innovation and sustainability are key in everything we do at Bosch Beton,” says Brechtje van den Beuken, co-CEO Bosch Beton....