Storage of biodigester residual products

It is vital that a biogas plant has access to clean, tidy and cost-efficient storage of raw materials. We installed our retaining walls at Omrin on Ecopark De Wierde in Heerenveen together with Joost Visser Infra.

Omrin (Friesian for ‘recycling’) collects waste for sixteen Friesland municipalities, three Groningen municipalities and over 7,000 companies. It also processes waste for around 800,000 households and many companies. The waste collector and processor aims to recover as many raw materials as possible from waste and produce sustainable energy from this. A third of the residual waste comprises organic material. For Omrin, this is a valuable raw material for the production of biogas and electricity.

Storage system

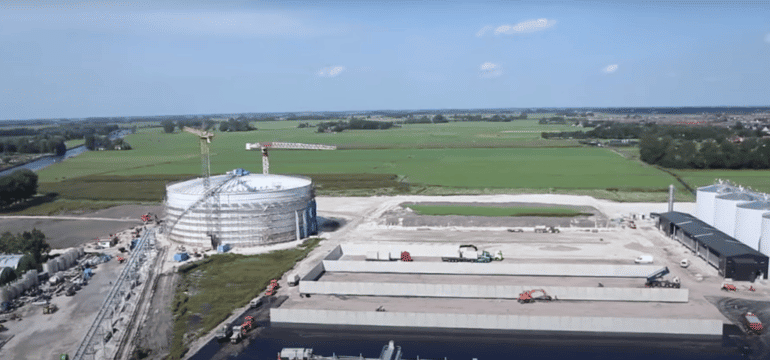

It is extremely important that a biogas plant has access to clean, tidy and cost-efficient storage of raw materials. We installed a storage system for residual products from the biodigester at Ecopark De Wierde in Heerenveen. The product dries here to reduce tonnage prior to transportation. We installed the residual product storage together with Joost Visser Infra, using our 3-metre high LA retaining walls.

Biogas

Organic material is fed into the biodigester plant at Ecopark De Wierde in Heerenveen, which then produces biogas. This biogas generation plant was installed at Ecopark De Wierde in 2016 and is the largest in the Benelux. The plant enables Omrin to convert the biogas they produce into green gas. They can produce up to 14 million m3 of green gas per year. They use around one million m3 of green gas for their own fleet, with the rest being injected on the Liander gas grid. This production is sufficient for the annual gas requirements of 10,000 households.

Further information

If you would like to know more about this project or our customised retaining wall solutions, please feel free to contact our consultants.

Build your own silage clamp

Use the handy Bosch Beton silage clamp generator to build your own virtual silage clamp in three easy steps. After you have submitted this to us, you will receive free customised advice within three days.

Project in the picture

Similar projects

Retaining walls for Danish biogas plant

To reduce CO2 emissions, biogas is a sustainable energy source that offers opportunities. At our Danish customer OL Biogas in Langå, we realised two silage clamps with our retaining walls for the biogas installation

Reliability and assurance for biogas plant

The biogas plant in Dartford, Kent, UK, wanted a trench silo with vertical walls. Bosch Beton’s concrete retaining walls provided security for the future.

Suikerunie stores 100,000 tonnes of pressed pulp

Eight silage clamps for the storage of 100,000 tonnes of raw materials for a fermentation plant of Suiker Unie Green Energy. Bosch Beton carried out the calculation, delivery and installation of the 420 elements in total