5 misconceptions about sustainable retaining walls

By its very nature, construction is something you do with a view to the future. What you construct now will still be there decades later. That demands a certain responsibility, which also applies to us as a manufacturer of concrete retaining walls. It’s also the reason that we, at Bosch Beton, have an ambitious goal: 100% circular production!

We have already taken various fantastic steps towards that goal in recent years. For instance, we produce retaining walls using solar power and filtered rain and wastewater. And earlier this year, we launched our third-generation concrete mixture, which uses 50% less cement. This reduces the carbon footprint of the retaining walls we produce by some 35% compared with traditional retaining walls.

We’ll continue to work on hybrid versions with even less cement in the coming years. In doing so we’re frequently confronted by the limits of current legislation and regulations. We have already produced the first cement-free geopolymer retaining wall. However, this sustainable wall falls outside all building norms and can therefore only be used in pilots. But it’s not only legislation and regulations that are curbing the transition to a circular future. Deeply ingrained misconceptions about sustainable construction in general and sustainable retaining walls in particular are also curbing the transition.

Misconception 1: we can build without concrete

It’s a misconception that we will be able to build entirely without concrete in the future. That is simply a utopia. Yes, we can use alternative materials more often than we do now. And yes, we can build in a leaner way, so we use less concrete. But for some applications, the structural features of concrete are simply irreplaceable. Take bridges, viaducts and flood defence barriers. Can you imagine constructing all these from wood or steel?

Misconception 2: a sustainable retaining wall is carbon neutral

As we’ll always need concrete, concrete retaining walls will retain their functionality in future construction, which is why we’re aiming to produce the most sustainable retaining wall possible. Our geopolymer walls enable us to create an A++ rating with minimum carbon emissions. Yet, for now, it is a misconception that this retaining wall will be completely carbon neutral. Even if we can manage entirely without concrete in the long term, we’ll still need steel to create structural strength and stability. And we’ll still need the blast furnaces for this…

Misconception 3: a sustainable factory makes retaining walls sustainable

Another ingrained misconception is that sustainable production automatically makes a retaining wall sustainable. Of course the production method is important, which is why we’ve also invested in an energy-neutral factory. But it’s only part of the puzzle. From raw materials extraction to transport and from the wall’s lifespan to its reusability: you need to consider the total picture when assessing a retaining wall’s sustainability. That’s why we’ve had a verified Life Cycle Assessment (LCA) conducted on our retaining walls. We are also involved in hydrogen pilots. The goal? To convert the renewable electricity we generate from over 18,000 solar panels into clean fuel for our trucks that deliver the retaining walls to construction sites. We’ll soon be taking the first steps in a hydrogen transport pilot to transport retaining walls for a new flood defence barrier in Arnhem.

Misconception 4: sustainable concrete is less safe

A fourth myth is that concrete with lower cement levels is less safe than standard concrete. Fortunately, that misconception is easy to debunk. We can measure material performance perfectly well by testing the compressive and tensile strength. Of course, such tests have been conducted on our new generation of retaining walls and the entirely cement-free geopolymer retaining wall. The tests show time and time again that our sustainable retaining walls can match traditional retaining walls in terms of strength and remain well above the current safety standards in the various concrete strength classes.

Misconception 5: sustainable concrete is more expensive

Let’s conclude with a final misconception, that sustainability is by definition more expensive. At Bosch Beton, we’re demonstrating the opposite by offering our sustainable third generation of retaining walls for the same price as standard retaining walls. We’ve made a conscious decision to cover the higher development and production costs ourselves temporarily, as this makes it achievable and affordable for clients to make sustainable choices. We’re doing this because we’re confident that this will contribute to developing a new standard in the market, with higher production volumes in the longer term and the associated economies of scale.

Finally: from idealism to standard

As a major Dutch retaining wall market player, we are able make such choices. At the same time we’re working hard for system change. Because to take real steps towards a circular future, it must become more attractive to make sustainable choices throughout the chain. An example? At Bosch Beton, we’re already partially replacing gravel with aggregate from crushed concrete. For that, though, we need clean recycled concrete rubble and the supply of such rubble is still limited as clients don’t often ask demolition contractors to demolish sustainably. They are often unwilling to pay the extra needed to ensure improved separation of demolition streams. We won’t resolve these types of challenges alone. They require partnerships in the chain and cooperation with government. This is the only way to move circular initiatives out of the realms of idealism. And that’s important because the future of our earth and of the sector are too valuable to rely on individuals and companies being willing to take the risks.

News

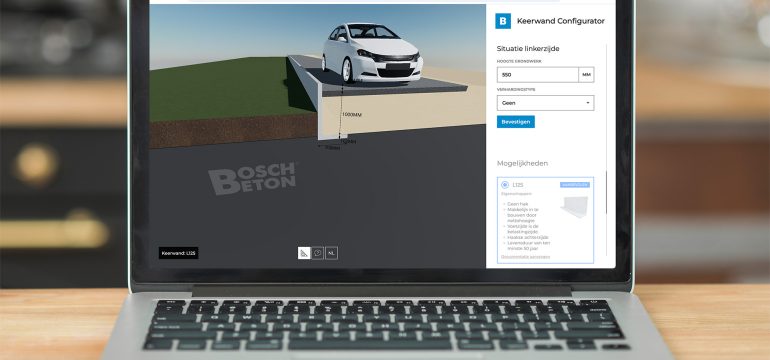

New: the Retaining Wall Configurator

Bosch Beton's Retaining Wall Configurator allows you to select a structurally sound retaining wall for your project in a few...

New: Green Series

“Innovation and sustainability are key in everything we do at Bosch Beton,” says Brechtje van den Beuken, co-CEO Bosch Beton....